ASSEMBLY AND TESTING COMPLEX OF SPACE VEHICLES (ATC SV)

GOAL

To create in Kazakhstan a technological and production base for the design, manufacture, assembly and testing of spacecraft, payload components and elements of space technology

COMPOSITION OF ATC SV

- a special design and technology bureau that ensures the implementation of all design and engineering work.

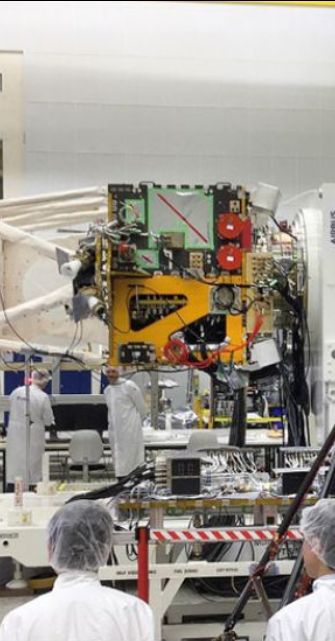

- an assembly and testing complex that provides a closed cycle for assembling and testing spacecraft weighing from 100 kg to 6 tons.

- Pilot production, which will have laboratories and production sites for the manufacture of individual components of spacecraft.

PRODUCTION CAPACITIES OF ATC SV

- Assembly and testing of spacecraft up to 6 tons with maximum dimensions of 3x3x6 m;

- types of tested spacecraft – telecommunication spacecraft, remote sensing, scientific and technological.

PRODUCTION STRUCTURE OF ATC SV

– area of thermal vacuum tests (TVAC);

-Area for measuring the inertial-mass characteristics of the spacecraft (MRM);

– Site of vibration tests (VIB);

– Acoustic test area (RevAC);

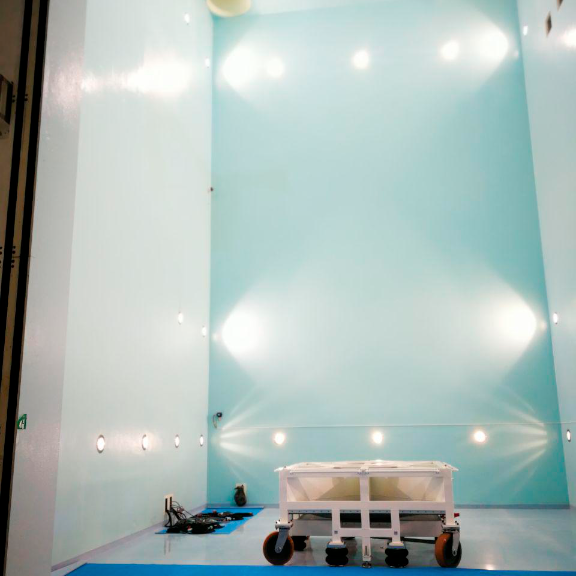

– Radio frequency test site (CATR);

– Test area for electromagnetic compatibility (EMC).

OPERATION